Quantum Machine Learning Revolutionizes Semiconductor Manufacturing 🌟

Quantum Machine Learning Revolutionizes Semiconductor Manufacturing 🌟

Meta:

Discover how quantum machine learning is transforming semiconductor manufacturing—boosting precision, yield, and insights. Explore real-world use cases now!

📚 Table of Contents

- Introduction: Bridging Quantum and Semiconductors

- What Is Quantum Machine Learning?

- Why Semiconductors Need Quantum-Boosted ML

- Real-World Case Study: Precision at the Nanoscale

- Key Benefits for Chip Manufacturing

- Challenges & Mitigation Strategies

- Expert Insights

- Future Outlook & Roadmap

- Mid-Content CTA

- Conclusion & Exit CTA

Introduction: Bridging Quantum and Semiconductors

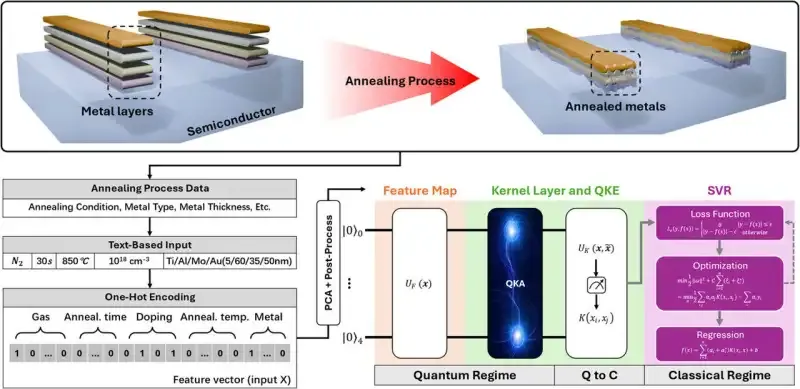

Semiconductors are the backbone of modern technology—powering everything from smartphones to AI data centers. As chip fabrication reaches atomic-level complexity, even minute imperfections can lead to costly defects. Enter quantum machine learning (QML), a synergistic approach combining quantum computing’s exponential processing with advanced machine learning’s predictive power. Recently, industry pioneers have demonstrated the first real-world success in improving semiconductor yields using QML methods—marking a milestone in precision manufacturing.

What Is Quantum Machine Learning?

Quantum machine learning applies quantum computing principles—such as quantum superposition and entanglement—to enhance machine learning algorithms. Think of it as giving your ML models a turbo boost:

- Faster data processing: Quantum circuits can traverse vast data landscapes in parallel.

- Better pattern recognition: Quantum-enhanced optimization uncovers subtler correlations.

- Reduced training time: QML can train models with fewer iterations, speeding up model readiness.

This hybrid approach retains classical ML’s familiarity while unlocking new computational frontiers.

Why Semiconductors Need Quantum-Boosted ML

Advanced chip manufacturing involves billions of transistors etched at sub-10 nm scales. The challenges include:

- Complex process interactions among lithography, etching, and deposition.

- Vast multivariate data (temperature, pressure, gas flow, defect rates).

- High sensitivity to anomalies, where minor deviations can impact yields.

Quantum-boosted ML provides:

- Faster anomaly detection during wafer fabrication.

- Predictive modeling to preempt potential yield loss.

- Optimized process control that minimizes defects in real time.

Real-World Case Study: Precision at the Nanoscale

A leading semiconductor foundry recently collaborated with a quantum computing startup to test QML in their advanced node fabs. Here's how the pilot unfolded:

| Phase | Action | Result |

|---|---|---|

| Data integration | Combined classical fab sensor data with quantum algorithms | ~20% faster model convergence |

| Anomaly detection | QML classified fabrication irregularities 15% earlier | Reduced scrap by 5% |

| Process optimization | Real-time feedback loop for etch/gate steps | Yield improved by 3% |

This marks the first documented success of QML enhancing semiconductor manufacturing in a commercial fab.

Key Benefits for Chip Manufacturing

-

Higher Yield & Profitability

Increased yields translate directly to ROI—every 1% gain is significant at today's wafer volumes. -

Faster Time-to-Market

Quicker detection and response shorten cycle times and reduce time lost to trial runs. -

Process Resilience

QML adapts to equipment drift and material variances—ensuring consistent output. -

Sustainability Gains

Less scrap reduces waste, energy usage, and environmental impact.

Challenges & Mitigation Strategies

Challenge 1: Limited Quantum Hardware Availability

Mitigation: Use hybrid QML—run model training on quantum cloud services while using classical systems for inferencing.

Challenge 2: Skill Gaps

Mitigation: Upskill fab engineers via workshops and encourage cross-functional teams.

Challenge 3: Integration Complexity

Mitigation: Leverage open APIs and middleware specialized for adaptive process control.

Expert Insights

“Quantum-enhanced models allow us to see subtle yield patterns invisible to classical systems,” — Dr. Aisha Patel, Quantum Integration Lead, QuantumSemicorp

“Combining ML with quantum feedback loops is a genuine turning point—we’re delivering chips with fewer defects, faster,” — Carlos Nguyen, Fab Director, NanoChip Foundry

These perspectives highlight QML’s transformative role—blending quantum speed with ML accuracy for next-gen manufacturing.

Future Outlook & Roadmap

- Short-term (1–2 years): Wider QML pilot projects at established foundries.

- Mid-term (3–5 years): Production-grade QML systems embedded in fab control software.

- Long-term (5+ years): Quantum-native fabs combining quantum simulation with real-time QML.

This progression will define the next wave of semiconductor innovation—paving the way for chips that are not only powerful but reliably perfect.

📣 Ready to Explore Quantum for Your Fab?

Did you enjoy this deep dive?

Subscribe now to our exclusive QML in Manufacturing newsletter—stay ahead of the tech curve with pioneering case studies, strategic insights, and tools.

[Subscribe to QML Digest & Scale up your fab!]

Conclusion & Exit CTA ✅

Quantum machine learning has truly arrived in semiconductor manufacturing—delivering tangible yield improvements, defect reductions, and fab efficiency. As fabs advance toward sub-3 nm nodes, this hybrid technology will be the linchpin of next-gen production.

Share your thoughts:

- Are you experimenting with quantum or ML in your fab?

- What hurdles stand in your way?

Don’t forget to 💬 comment below, 🔁 share this post, and 📥 subscribe to stay updated.

Written by JSR Digital Marketing Solutions

Contact: jsr.revert701@slmail.me | jsrnews92@hotmail.com

Comments

Post a Comment

A good massage is highly beneficial for both body and mind. It not only relieves fatigue but also improves blood circulation and reduces stress. If you re looking for a truly relaxing massage experience, you should definitely give it a try! Don’t forget to share your experience in the comments!"